what is hardness and how is it tested|hardness tester for thin material : dealer 1. Rockwell Hardness Testers. Rockwell hardness testers are the most commonly used of all the types of hardness testers. The Rockwell method offers a quick and accurate measure of hardness on almost all metals and . 4 de fev. de 2024 · 25. GAMES ALLOWED. Scratch Cards, Video Poker, Blackjack, Roulette, Craps, Keno, Bingo, Slots. The bonus is valid for the following games: Neon Wheel 7s. Open a new account at Slots Plus and get 400% match bonus + 80 free spins on Neon Wheel 7s with a minimum deposit of $25 using the code CALI80. Valid for casinos. Slots .

{plog:ftitle_list}

web732. 83. 50. clear. 728. 119. Climb the ranks of VALORANT with our leaderboard tracker, showcasing the top players, and their competitive standings. Compare your performance with the best, and set your sights on reaching the top.

why is hardness testing important

solomon seals test

types of hardness testing methods

What Is Hardness Testing? Hardness testing assesses a material’s ability to resist permanent deformation at its surface by applying pressure with a harder material. It finds applications across various industries for comparing and selecting materials, as well as ensuring quality control in .Around 1900, Martens proposed the following definition for hardness testing: “Hardness is the resistance of a body to the indentation by another (harder) body.” This simple but precise definition has taken its place in technical . Hardness is the resistance with which a material opposes the penetration of another (harder) body or simply says the resistance to deformation (scratching, indentation, .

1. Rockwell Hardness Testers. Rockwell hardness testers are the most commonly used of all the types of hardness testers. The Rockwell method offers a quick and accurate measure of hardness on almost all metals and .Hardness Testing. Discover the intricate world of hardness testing in materials engineering. This comprehensive guide delves into the definition, standards, procedure, and vital .About Hardness Tests. The hardness test developed by Friedrich Mohs was the first known test to assess resistance of a material to scratching. It is a very simple but inexact comparative test. Perhaps its simplicity has enabled it to become .

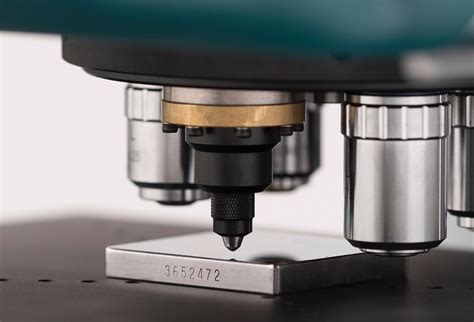

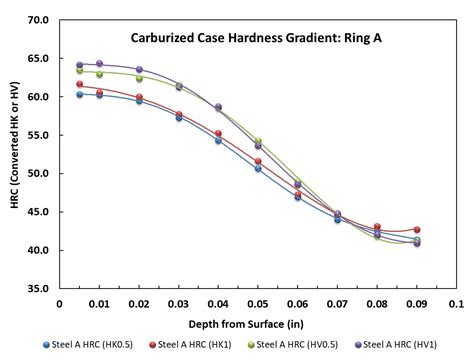

Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load).The Vickers hardness test method can be also used as a microhardness test method, which is mostly used for small parts, thin sections, or case depth work. Since the test indentation is very small in a Vickers microhardness test, it is .

sonax spray and seal test

Brinell Hardness Test: Rockwell Hardness Test: In Brinell Hardness Test the indenter is a spherical Tungsten Carbide Ball: For the Rockwell Hardness Test, the Indenter is a Small Steel Ball (HRB) or a diamond cone (HRC) Hardness greater than 650 HB can not be measured with the Brinell Scale setup. There is no such limitation in Rockwell .When testing coatings, scratch hardness refers to the force necessary to cut through the film to the substrate. The most common test is the Mohs scale, which is used in mineralogy. One tool to make this measurement is the sclerometer. Another tool used to make these tests is the pocket hardness tester.Mohs hardness, rough measure of the resistance of a smooth surface to scratching or abrasion, expressed in terms of a scale devised (1812) by the German mineralogist Friedrich Mohs. The Mohs hardness of a mineral is determined by observing whether its surface is scratched by a substance of known or . If the species being tested is fine . 🧴Method 1: Simple Soap Test. The soap test is a great way to determine water hardness.It won’t tell you exactly how hard or soft your water is, but it’s a quick and easy indicator of whether or not you have hard water.. You will need: A clear plastic bottle with a lid; Pure liquid soap; A water sample from your faucet

Hardness testing is a vital process in many industries. Our guide explains everything you need to know about this crucial technique. From testing methods to the key applications, we cover it all to help you stay informed. Hardness testing is a vital process in many industries. Our guide explains everything you need to know about this crucial . In scientific terms, water hardness is generally the amount of dissolved calcium and magnesium in water. But in layman's terms, you may notice water hardness when your hands still feel slimy after washing with soap and water, or when your drinking glasses at home become less than crystal clear. Learn a lot more about water hardness on the Water Science . Brinell Hardness Test. The Brinell hardness test entails measuring the diameter of indentation caused by a constant concentrated force applied by a steel or carbide spherical indenter on a test specimen. The steel ball indenter is first placed in contact with the material before a constant force is applied and maintained for a 10 to 15 second duration, known as the .

In Rockwell hardness testing, HRA, HRB, and HRC represent three different scales: Scale A, Scale B, and Scale C. The Rockwell test is a common indentation hardness test. All three scales begin with an initial pressure of 98.07N (10kgf), and the hardness value is calculated based on the depth of indentation.

First, you have to measure the water hardness with a water hardness test. You can get it online for less than . If you measure that your water hardness is below 60 ppm or 3.50 GPG, you don’t have to worry about hard water. By classification, you have soft water.

Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and .

Brinell hardness test is an indentation hardness test.It uses a hard spherical ball (usually around 10mm in diameter). An applied force (a typical test will use 3,000 kilograms) pushes the ball against the surface of the material for a set amount of time (between 10 – 30 seconds, known as the dwell time).

Measuring the hardness of materials is a fundamental aspect of material science and engineering, involving various test methods each suited to specific types of materials and applications. These methods not only help in .There are a number of different methods of testing the hardness of a material through indentation. The three most commonly used are the Brinell test, the Vicker’s Diamond test, and the Rockwell test. All three methods involve indentation of the material. The hardness is calculated by measuring the force applied and comparing this to some .See also: Hardness. Brinell Hardness Test. Brinell hardness test is one of indentation hardness tests, that has been developed for hardness testing. In Brinell tests, a hard, spherical indenter is forced under a specific load into the surface of the metal to be tested. Hardness tests are extensively used to characterize a certain material and to identify if it is appropriate for its intended purpose. All hardness tests involve the utilization of a particularly shaped indenter that is harder than the material under testing. The indenter is pressed onto the test surface with the use of a certain amount of force.

The Rockwell hardness test method is a simple process that uses a diamond cone with a round tip for harder materials and a hardened steel ball indenter for softer ones. With every test, two loads are applied to the test subject. First, an indenter is forced into the test subject under an initial load of 10kg-f, and the depth is recorded.

In the Rockwell hardness test, the measure of the hardness is not an indentation surface but an indentation depth. Either a carbide ball or a rounded diamond cone with a tip angle of 120° and a tip radius of 0.2 mm serves as the indenter. The indentation depth can be read directly from a dial gauge via the traverse path of the testing machine. Rockwell Hardness Test: This test measures the depth of penetration of an indenter into the material. The Rockwell hardness test is the most commonly used hardness test in the industry due to its simplicity and accuracy. Brinell Hardness Test: This test measures the diameter of an indentation made on the surface of the material by a hard steel .In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter, is measured.In contrast, the size of the indentation is measured in the Brinell, Vickers and Knoop optical test methods.. The deeper a defined indenter penetrates the surface of a specimen with a specified test load, the softer the material that is being tested.

The Janka hardness test results tabulated below followed ASTM D 1037-12 testing methods. Lumber stocks tested range from 1" to 2" (25–50 mm) thick. The tabulated Janka hardness numbers are an average. There is a standard deviation associated with each species, but these values are not given. [citation needed] No testing was done on actual .A Rockwell hardness tester. The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). [1] There are different scales, denoted by a single letter, that use different loads or indenters.

The Vickers hardness test is suitable for a wide range of applications, including micro hardness testing. On this page, you can find a description of the Vickers hardness test, practical information on how to apply it and a list of our micro hardness testing machines for Vickers. The Vickers hardness test at a glance: Ideal for micro hardness .

The Mohs hardness scale rates the hardness of minerals based on their ability to scratch softer ones. The Mohs hardness scale is a qualitative test that measures the hardness of a mineral by its ability to visibly scratch softer minerals. The scale isn’t perfect, but it’s a great tool for quick identification of rocks in the field.

Common hardness testing methods are introduced below. Rockwell Hardness. This method tests the hardness of steel parts by applying loads to parts via either a tungsten carbide ball or a spheroconical diamond indenter. A part’s testing surface and seating surface must be properly prepared prior to testing.

WEB4.700021. (21) £17.00. Add to trolley. Add to wishlist. Page 1 of 1. Cocktail glasses Drinking glasses and glassware at Argos. Order online today for fast home delivery.

what is hardness and how is it tested|hardness tester for thin material